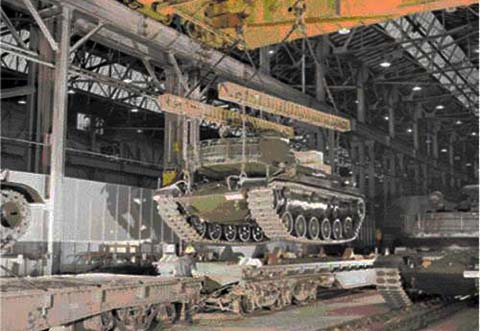

At the start of WWII, America’s tank program was non-existent, and the German’s blitzkrieg strategy was incredibly powerful. “Because of its strength as an automobile manufacturer, Detroit was an ideal city to step up to the task set by the President. Thus, the Detroit-area’s automobile industry underwent rapid transition in order to handle the production of weapons and vehicles of war.” [8]. Not long after the events of Pearl Harbor, Detroit received 350,000 workers from around the country. The U.S. needed an armored force alongside its infantry, so halfway through 1940 the Detroit Arsenal was created. “Simultaneously and working in perfect coordination, other Chrysler men plan the layout of the arsenal building itself. …On August 15th, it was authorized to construct a 20 million dollar tank arsenal” [1].This behemoth factory stretched 5 city blocks long and 2 wide on land that is now Warren, Michigan. The Detroit Arsenal was the first ever mass-production tank plant in the U.S. “Overnight, the automobile industries of America transformed its plants, reshaped its tools to become the greatest tank arsenal the world has ever known.” [7]. The design of the structure was completely state-of-the-art. Thousands of new tools and technologies had to be manufactured and shipped to Warren in order to maximize the arsenal’s production rate. Miles of assembly lines ferrying untold numbers of parts and materials snaked throughout the plant. Thousands of workers, worked tirelessly to meet deadlines. Massive cranes hoisted tons upon tons of steel, turrets, chassis, and even whole tanks, onto conveyor belts to be machined and welded. At the back of the facility, trains carried finished M3 Lees and M4 Shermans out of the plant onward towards the coast to be shipped to the Allies in Europe. “Like shrouded ghosts, they roll out on trains of flatcars headed for the sea. …Reinforcements for the armies of the United Nations.” [7]. Detroit Arsenal was truly a masterpiece of American ingenuity and technology. Without its outstanding rate of production and the non-stop labor by its worker’s, the outcome of the war could be very different.

The plant was run by Chrysler, whom had received a contract to build 1,000 M3 tanks in 1940. The plant wasn’t even finished being built by the time the first M3 rolled off the line, “One year after the first dedication 2,000 tanks had been made.” [12]. Due to the M3’s major design flaws, American engineers had to design a new, more effective tank. Thus, the M4 Sherman was created. The M4 was far more reliable than the M3 in terms of reparability, and armament: “Designed from the drawing board to be produced as quickly as possible on the very same factory lines which were already delivering hundreds of M3s monthly, the M4 was kept as close as possible to its predecessor, including suspension, tracks, transmission, although with an entirely brand-new upper hull.” [6]. However, the Sherman was still very vulnerable to the German’s Panzers and Tigers. Although the Sherman fired the same 75mm round as the Panzer, the barrel was designed for low velocity, making its penetrating power far less. This was designed to increase the longevity of the barrel, but most Shermans didn’t survive long enough to see a difference. “The armor, at 81mm, was considerably thinner than the Panzer’s and unable to withstand its armor-piercing ammunition.” [9].

Fortunately for the Americans, German production rate of their tanks couldn’t keep up. The production rate of the factory was incredible, out-producing the German’s Panzers at a rate of over 8 to 1. In December of 1942, the plant had produced 896 M4s, with only 5,000 workers, in that month alone. The massive number of tanks being built was vital for the war effort. The Sherman had significantly less armor and firepower than the German’s medium and heavy tanks, but was cheap and easier to produce. The M4’s lighter armor made it faster and more maneuverable than the Panzer on the cold harsh terrain of Western Europe. The Sherman was also far more reliable, Panzers were often prone to malfunctions and breakdowns. This was a major detriment for the German armored division. Combine the Sherman’s speed and versatility with Detroit’s enormous production rate, the German’s couldn’t stand a chance. The American tank commanders didn’t have to take on the Germans alone because the US Army enjoyed complete air superiority throughout the invasion of Europe. Rocket strikes on front-line tanks while bombers annihilated German production facilities, greatly assisted the Army ground troops.

The American tanks had to greatly outnumber the German’s in order to achieve victory. Overall, Detroit arsenal had built a total of 22,234 of the close-to 50,000 tanks in WWII. Due to the extremely low number of German tank support, German ground troops had to rely on small arms and fixed artillery to defend against the American swarm. This proved futile due to the German artillery’s lack of mobility. Although American tank crews received massive casualties, the impossibly large amount of tanks that Detroit Arsenal produced allowed the Americans a steady push through France into Germany. At the end of the war America’s tank production halted, by order of the government. “During World War II, the Detroit Arsenal Tank Plant built a quarter of the 89,568 tanks produced in the U.S. overall. Its production closely matched tank production of either Great Britain or Germany.” [11:1]. Detroit Arsenal’s success wasn’t only felt in WWII, its tank production boosted the US Military in almost every American war since.

Detroit Arsenal was sold to General Dynamics in 1982, and would begin production of the US Military’s current tank; the M1 Abrams. The M1 has been in service for decades now, and has proven itself throughout the Gulf-War, and the War on Terror. Its armament includes a 120mm smooth-bore cannon, a .50cal turret, and duel M240 belt fed machine guns. Its engine is one-of-a-kind, a multi-fuel turbine jet engine, pumping 1,500 horsepower which allows it to reach speeds of over 40 mph. Detroit Arsenal’s tank plant was eventually closed in 1996 and is currently a US Army base for research and development.

Overall, Detroit Arsenal has contributed more towards American warfare than any other facility in the US. Its production of Tanks and other vehicles in WWII was greater than Great-Britain and Germany combined. Its vast assembly lines and endless conveyor belts had in many ways, shaped America into the mighty military power it is today. Without the massive amount of tanks that rolled out of Detroit monthly, America would have likely lost the war. Today, Detroit Arsenal is but a monument to the ingenuity and perseverance of Americans. It shaped the industrial and military powerhouse that the United States has become. “Here in the Detroit Tank Arsenal… devoted entirely to the mass production of the tank, we forge the armaments of victory.” [2]. The facility’s advancements in tank technology still assist American soldiers almost 20 years after its closing. Without the production of Detroit Arsenal, and it’s close to 90,000 total tanks built, America could likely be a very different place than it is today.

Primary Sources

1) Assembly Lines of Defense. Youtube.com, 1941. Film.

2) Building a Tank: A Defense Report on Film 1941. Youtube.com, 1941. Film.

3) Detroit Army Arsenal. Digital image. Wikipedia. Wikimedia, 19 Aug. 2015. Web. 1 Dec. 2015.

4) Detroit Arsenal Army Base in Warren MI. Digital image. MilitaryBases.com. None, n.d. Web. 1 Dec. 2015.

5) Detroit Arsenal. Digital image. Tacomlcmccommunityreport.com. None, n.d. Web. 1 Dec. 2015.

6) M4 Sherman (1942). Tanks Encyclopedia. 28 Nov. 2014. Web. 10 Nov. 2015.

7) Tanks by the Thousands Roll off the Line. Buyoutfootage.com, 1942. Film.

Secondary Sources

8) “Arsenal of Democracy.” Detroithistorical.org. Detroit Historical Society. Web. 15 Nov. 2015.

9) Hart, James. “The M4 Sherman vs the German Panther.” Warfare History Network. 26 June 2014. Web. 20 Nov. 2015.

10) Levin, C. (2000). Detroit Arsenal Tank Plant.

11) Pike, J. (2011, May 7). Detroit Arsenal, Detroit Army Tank Plant (DATP).

12) The Arsenal of Democracy. (2013, May 1). Michigan History Magazine.