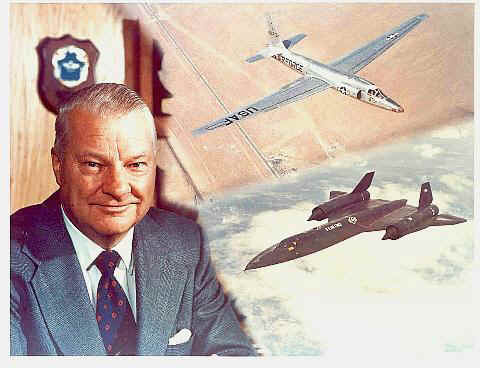

Kelly Johnson was one of the most influential aerospace engineers of the 20th century and is considered to be the father of Lockheed Martin’s Skunks Works program that developed some of the most iconic and advance military aircraft of our time. He was a brilliant engineer but is most revered for his ability to direct and manage the projects that Skunk Works undertook with incredible efficiency. He also was know for creating an efficient and extremely productive work environment. Many of the projects that he directed were completed with small groups of dedicated people that were given a large role and responsibility in the creation of their aircraft. Projects were often times completed at a much lower cost and in a much shorter time span than more conventional design management systems. They were also able to produce some of the most advanced and iconic aircraft in history, including the SR-71 and the U-2 spy plane.

The Origin of “Kelly” Johnson

Clarence Leonard “Kelly” Johnson was the son of Swedish immigrants and was born in the mining town of Ishpeming Michigan in 1910. He graduated from the University of Michigan in 1993 where he had begun conducting wind tunnel tests on an aircraft that Lockheed was designing. After graduation he was given the opportunity to work at Lockheed as a tool designer. It was as a tool designer that he convinced Hall Hibbard, the chief engineer of Lockheed’s model 10 that Kelly had tested in wind tunnels in his studies at U of M, that the aircraft was unstable. He was able to prove this and modify the design of the aircraft, increasing its stability. Recognizing his intuition and skill in designing aircraft, Lockheed promoted him to an aeronautical engineering position. Kelly went on to fill a number of roles at Lockheed as he honed his skill as an engineer. He was assigned the role of test engineer, stress analyst, aerodynamics engineer, and weight engineer. This enabled him to have a complete understanding of the design process involved in engineering at Lockheed. In 1938 he was promoted to chief research engineer. In 1956 he became the Vice President of Research and Development and the Lockheed-California company. From there he would begin to build the iconic division of Lockheed know as “Skunk Works”.

The Birth of Skunk Works

In the early 1940’s, Germany was losing the war but had managed to develop the first jet engine powered aircraft that the world had ever seen. In response, the U.S. Airforce contracted Lockheed to develop the first American Fighter Jet. Kelly Johnson was given full control over the project and answered only to the head of Lockheed himself. They were given 5 months to develop the aircraft and in 143 days, Kelly and his hand picked team were able to deliver the P-80 Shooting Star. This solidified Kelly’s legacy of delivering on time, and under budget.

Greatest Accomplishments

F-104 Starfighter: After visiting pilots in Korea, Kelly Johnson was made aware that US aircraft were at a disadvatange to the Russian MIG-15’s. The Amercan Made F-86 Sabre would need a replacement so Kelly and his team at Lockheed began to work on an aircraft that would outperform the MIG’s and give the American pilots the advantage that they needed to maintain air superiority.

The American pilots had determined that they needed a faster plane that could climb better and fly higher. Kelly and his team at Lockheed had already started working on the plane when they signed a contract with the Airforce to develop what would become the F-104 Starfighter. The Starfighter was impressive, even by modern standards, in its flight characteristics. It was fast, maneuverable and could climb extremely well. It’s downfall was at low speeds however. It was designed to operate at high speeds and did so very well but needed to maintain these high speeds in order to turn. It also had an extremely high takeoff and landing speed that troubled pilots.

SR-71 Blackbird:

The SR-71 is undoubtedly still one of the greatest planes to ever exist. It was so far ahead of it’t time that it continued to set records until the very end of its life. The aircraft had to be made almost entirely from titanium, a cutting edge material at the time. Even the tooling for the plane had to be custom made to prevent corrosion. The SR-71 set world records for speed and altitude and could fly so fast and high that it’s main defense strategy was to just outrun anything that threatened it. Thousands of missiles have been fired at the SR-71 and not one ever was able to make contact. Eventually, the air force had to retire the aircraft due to the high cost of operation. It took large crews to maintain the aircraft and parts were scarce. In the end, the SR-71 would become relatively obsolete as satellite surveillance became the favored method to observe places of interest in the world.

Legacy

Kelly’s 14 rules of Skunkworks:

- The Skunk Works® manager must be delegated practically complete control of his program in all aspects. He should report to a division president or higher.

- Strong but small project offices must be provided both by the military and industry.

- The number of people having any connection with the project must be restricted in an almost vicious manner. Use a small number of good people (10% to 25% compared to the so-called normal systems).

- A very simple drawing and drawing release system with great flexibility for making changes must be provided.

- There must be a minimum number of reports required, but important work must be recorded thoroughly.

- There must be a monthly cost review covering not only what has been spent and committed but also projected costs to the conclusion of the program.

- The contractor must be delegated and must assume more than normal responsibility to get good vendor bids for subcontract on the project. Commercial bid procedures are very often better than military ones.

- The inspection system as currently used by the Skunk Works, which has been approved by both the Air Force and Navy, meets the intent of existing military requirements and should be used on new projects. Push more basic inspection responsibility back to subcontractors and vendors. Don’t duplicate so much inspection.

- The contractor must be delegated the authority to test his final product in flight. He can and must test it in the initial stages. If he doesn’t, he rapidly loses his competency to design other vehicles.

- The specifications applying to the hardware must be agreed to well in advance of contracting. The Skunk Works practice of having a specification section stating clearly which important military specification items will not knowingly be complied with and reasons therefore is highly recommended.

- Funding a program must be timely so that the contractor doesn’t have to keep running to the bank to support government projects.

- There must be mutual trust between the military project organization and the contractor, the very close cooperation and liaison on a day-to-day basis. This cuts down misunderstanding and correspondence to an absolute minimum.

- Access by outsiders to the project and its personnel must be strictly controlled by appropriate security measures.

- Because only a few people will be used in engineering and most other areas, ways must be provided to reward good performance by pay not based on the number of personnel supervised.

Primary Sources

- “Kelly Johnson’s 14 Rules and Practices.” Lockheed Martin.

- “Kelly Johnson: Architect of Air.” Lockheed Martin

Secondary Sources

- Leland R. Haynes, Webmaster. Clarence L. Kelly Johnson Biography.

- Garrison, Peter. “Head Skunk.” Air & Space Magazine, Air & Space Magazine, 1 Mar. 2010.

- “Kelly Johnson, Design Pioneer of Lockheed Aircraft, Dies.” Los Angeles Times, Los Angeles Times, 22 Dec. 1990.

- “CLARENCE L. ”KELLY.” NAE Website, .