10 miles South of Joliet, Illinois stand the remains of the Joliet Arsenal. Considered one of the largest and most advanced facilities of its time, this plant fueled the United States’ war effort by providing the essential artillery ordnance that softened enemy defenses and supported the infantry throughout World War II.

The strategies and tactics of World War 2 were dramatically different from those used in World War 1; high casualty trench warfare was avoided whenever possible, largely with the aid of the advanced technologies now available in the forms of improved aircraft, tanks, and artillery. The Germans used blitzkrieg tactics to circumvent and annihilate points of concentrated resistance or fortifications; the British used mass bombing raids to attack industrial output and destroy fortifications days before advancing troops reached the area; and the Russians used a wall of tanks and men to roll over the German lines. The United States likewise developed new strategies, originally planning to rely on bombers to cripple enemy forces and fortifications and then using infantry with supporting tanks to take the now softened area. This strategy soon needed revision;

Experience soon exposed the error of these notions. Fighting in North Africa, at Stalingrad, on Pacific islands, and in Italy proved there was no substitute for big, powerful guns to blast enemy fortifications or lay down a curtain of fire before advancing foot soldiers. No lesson of World War II was Plainer than this. Only heavy artillery could provide sustained, accurately placed fire on a ‘round-the-clock basis regardless of weather Conditions. ([5], p. 68)

Initially, American war planners thought heavy artillery was outmoded by comparison to the newly developed bombers and questioned their ability to keep pace with the rapid troop movements. It was believed that aerial bombardment could replace heavy artillery barrages as the principle method of softening enemy fortifications and destroying their personnel, which would aid in reducing American casualties and prevent the regression to trench warfare. But bombers could only fly during favorable weather, which limited their battlefield effectiveness and placed additional constraints on troop movements. Additionally, before the introduction of accurate bombsights their accuracy was sporadic at best and often limited bombing operations to area bombing, which often prevented adequate destruction of fortifications or moving infantry columns. Artillery was still the best method of destroying specific targets accurately at long range, regardless of time or weather, and were able to keep pace with troop movements by towing the guns behind jeeps, trucks, and tanks.

Realizing the limitations of aerial bombardments, there was a push by many generals to begin producing heavy artillery that could match the German heavy and siege artillery already in the field. The requests ranged from increased production of 240-mm howitzers up to a request from Lt. Gen. Lesley J. McNair, who was Commander of the Army Ground Forces at the time, for production of 16-inch railway guns to counter act the German super-heavy artillery (Thomson and Mayo; page 100-101). Despite the requests, the General staff continued to resist increasing the production of heavy artillery in hopes to conserve steel for weapon and ship construction, which resulted in limited quantities of heavy artillery and ammunition. This attitude changed dramatically towards the end of the war in 1944 when heavy artillery production was ordered to be expedited after the Italy campaign had proven that the German artillery could regularly outrange and out gun available American artillery. This was noted during a congress hearing, as follows:

Mr. Nelson: On artillery, there are tremendously increased requirements.

Senator Ferguson: Due mostly to changes in plan?

Senator Truman: Due mostly to the fact that they found out aircraft bombing could not take the place of artillery.

Mr. Nelson: That is very true.

Senator Hatch: This is one of the lessons of war.

Senator Ferguson: In other words, the dropping of the bomb didn’t have the same effect as the shooting of the shell.

Mr. Nelson: The Ordnance Department knew that from the very start.

Senator Ferguson: And contended for it?

Mr. Nelson: Contended for it; proved it mathematically in every way, shape and form.

Senator Truman: But you couldn’t convince them except by experience.

([5], p. 102-103)

Having learned that bombers could not take the place of heavy artillery for reliability or accuracy, all production of heavy artillery, including 155-mm, 240-mm, and 8-inch weapons, was increased to counter-act the presence of German heavy and super-heavy artillery, which included 150-mm howitzers, 600-mm self-propelled siege howitzers, and railway guns of 280 to 800-mm. German heavy artillery was often able to outrange their American counter-parts by 1 kilometer or more and were often supported by concrete fortifications with fixed heavy guns. The number of German heavy artillery was limited, however, due to the shrinking supply of raw materials available for production of weapons and ammunition – only being able to produce roughly 5,500 150-mm howitzers, fewer than 50 railway guns, and only seven 600-mm howitzers during the war – as well as being distributed between the three fronts of Russia, Italy, and the French coast. American industry was able to produce more artillery than the Germans, producing over 10,000 155-mm howitzers, 500 8-inch howitzers, and 300 240-mm howitzers by the end of the war.

Field commanders, unlike the General Staff and Army planners, realized the advantages of artillery early in the campaigns and adjusted tactics and strategies to utilize their fire power.

The settled doctrine of U.S. Army field commanders in World War II was to pave the way for advancing foot soldiers by massed artillery fire and aerial bombing. Whenever possible, stubbornly held positions were reduced at long range with steel and high explosives, not with frontal attacks by infantry columns … U.S. Army tactics helped achieve the all-important goal of sure victory at minimum cost in American lives, but they ate up ammunition at a rate never before considered feasible. ([5], p. 104)

By combining the power of accurate, sustained barrages from artillery units and the increasing payload capabilities of bombers that could be dropped on wide areas the field commanders had developed a working method to destroy fortifications while reducing their own casualties. With the concrete bunkers ruined, the machine-gun nests destroyed, the lines of barbed wire broken, and enemy infantry reduced in number or taking shelter, the American Army was able to gain ground by expending copious amounts of ammunition instead of losing men to withering firepower.

To supply the growing demands for artillery munitions resulting from the new and developing tactics, the Ordnance department began building Government Owned, Contractor Operated (GOCO) facilities to produce the necessary components of ammunition as well as perform final assembly of the shells, the Joliet Arsenal was one such installation. Originally built as two conjoining facilities, the Kankakee Ordnance Works which produced the TNT and DNT that was used in the artillery shells, and the Elwood Ordnance Plant which performed final shell assembly and produced fuzes, primers, boosters, and detonators. The TNT produced by the Kankakee Works could be sent directly to the Elwood Plant for use in production of artillery shells, mines, and bombs which could then be loaded onto train cars for shipment to distribution facilities.

The two facilities were operated by independent contractors during the war, Kankakee Ordnance Works being operated by Du Pont until 1944 when the contract changed to the U.S. Rubber Company and Elwood Ordnance Plant was operated by Sanderson and Porter. Du Pont was an experienced chemical and explosives production company while Sanderson and Porter was a firm of engineering and science, but the U.S. Rubber Company had traditionally been a synthetic tire manufacturing company with limited experience in manufacturing small-arms ammunition during the war and no prior knowledge in manufacturing artillery ordnance. This type of contracting was quite common during the period, as General Campbell explained:

‘One of the lessons Ordnance learned in the Second World War,” wrote General Campbell, “was that any up-to-date, alert manufacturing company with a strong executive, engineering, and operating staff could take an ammunition plant and operate it effectively, even though the plant was of a character entirely foreign to the previous activity of the company.’ ([5], p. 113)

This is understandable since these companies were often involved in large-scale industrial manufacturing they were already familiar with the financial, material, and personnel requirements of such large production facilities. These companies were able to manage the large scale production without excessive expenses and were able to establish sustained material intake that could support the quotas that the Ordnance Department placed throughout the war. The result was large production numbers and greater quality at limited cost to the government, which appealed greatly to government officials who controlled the budget as well as military officers who requested and used the ammunition.

Like many other facilities constructed and operated during the period, the Joliet Arsenal plants were built with the intention of multi-purposed functions, with each plant producing multiple components required during the final production ([2], p. 111). The results of this multi-purposing allowed for more rapid adoption of technologies and techniques as they became available without sacrificing the production of the entire facility; a few lines could be changed at a time while the other production lines continued normal operations. The ability to change lines independently also allowed for quick responses to the changing requirements of the soldiers and commanders, as seen in the Elwood Plant:

Throughout the 1942-1945 period, ammunition production lines and machinery at Elwood were continually modified in response to changing materiel needs for the war effort … But by the beginning of 1944 production was limited mainly to 105-mm howitzer ammunition; one kind of each fuze, booster, primer, and detonator; an anti-tank mine dummy; and a demolition block. In May 1944 the plant began construction and renovation to allow the loading of 155-mm, 8-inch, 240-mm, and additional 105-mm projectiles. ([4], p. 38)

As the Allied invasion of Axis-controlled Europe commenced it was realized that the 105-mm howitzer, while versatile and useful, was unable to match the range and fire-power of German heavy artillery and lacked the capability to adequately engage fortified concrete bunkers that had been constructed by the German Army. The solution was to use more heavy artillery, which created a need for more heavy artillery ammunition, a need that the Elwood Plant was able to meet by converting production lines from 105-mm and fuze production to the production of the larger shells while still being able to manufacture the more commonly used 105-mm shells on other lines that remained in operation during the conversion. This flexibility also allowed for the introduction of volumetric-multiple-pour machines in 1945 that were capable of simultaneously loading sixty shells rather than hand-pouring the TNT into the shells individually, a process that was labor-intensive and was prone to inconsistencies in the final product. The introduction of this new machine greatly increased the number of shells produced, reduced the time it took to produce each shell, and improved the consistency and quality of the shells being produced.

The Kankakee Works was likewise built with the intension of multi-purposed production, not only producing TNT and DNT but also produced several raw materials such as nitric acid and sulfuric acid which could be used in the explosives production. Kankakee also benefited from advances made in TNT production with the introduction of reverse nitration, a process introduced to the United States by Lt. Col. John P. Harris after a visit to a Canadian TNT plant near Montreal. The process was actually just a reversal of the process already in use:

In the early stages of the war, the acid was added to the toluene mix, a process known as nitration. It later was discovered, however, that the toluene could be added to the acid, a “reverse nitration” process that was safer and increased production. ([4], p. 33)

By adding the toluene to the acid the result was a more complete nitration of the compounds in the various stages of production, a reduction in production time, and fewer dangers which were inherent with manufacturing TNT. The production results across all TNT manufacturing plants was a tripled output, with plants designed to produce 15 tons per day increasing production to 50 tons per day, which also resulted in a halved price from 12 cents per pound to 6 cents per pound. This increased quantity of TNT also resulted in the elimination of TNT substitutes that had been used in an attempt to extend the limited supplies of TNT. With more TNT available, the Elwood Plant was able to increase production of shells, mines, and bombs which in turn increased the available supplies of ammunition on the front lines.

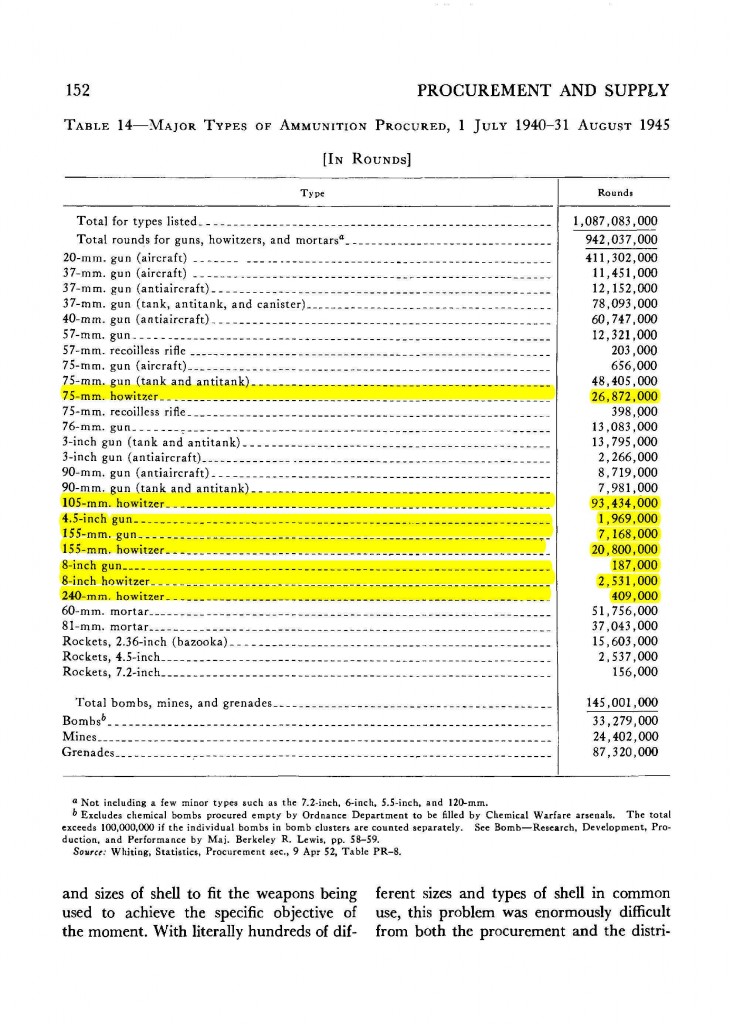

The overall results of such facilities as the Joliet Arsenal was a continuous available supply of ammunition that could change production with the ever dynamic situations on the front lines. As is seen in Table 14, the use of GOCO facilities allowed for a massive quantity of ammunition to be produced by the conclusion of the war in 1945. Such arsenals produced a total of 153,370,000 rounds of artillery ammunition – 93,434,000 rounds produced for the 105-mm howitzers alone and 31,095,000 rounds for the use of heavy artillery such as the 155-mm, 240-mm, and 8-inch howitzers. The vast amount of artillery ammunition produced during the war allowed field commanders to destroy enemy fortifications before the infantry moved in, effectively expending artillery shells rather than human lives. The artillery paved the way for the troops and the arsenals back home, such as the Joliet Arsenal, provided the ammunition to make such tactics possible through the effective management by contractors and technological innovations to increase productivity.

Primary Sources

- General Campbell. Memo Written by General Campbell. The Ordnance Department: Procurement and Supply (Thomson, Harry C. and Mayo, Lida pg 113). 1960

- Congressional Hearing (April 1945). The Ordnance Department: Procurement and Supply (Thomson, Harry C. and Mayo, Lida pg 102-103). 1960

- Table 14. Major Types of Ammunition Procured, 1 July 1940 – 31 August 1945 (9 April, 1952). The Ordnance Department: Procurement and Supply (Thomson, Harry C. and Mayo, Lida pg 152). 1960

Secondary Sources

- Rathbun, Peter. “Joliet Army Ammunition Plant” Historic American Engineering Record. 1984

- Thomson, Harry C. and Mayo, Lida. The Ordnance Department: Procurement and Supply. 1960

- GlobalSecurity.org. “Joliet Army Ammunition Plant”, Military Facilities, May 7, 2011.

- USDA Forest Service, fs.usda.gov. “The Joliet Army Ammunition Plant” Midewin National Tallgrass Prairie-History & Culture.

- Military Factory, MilitaryFactory.com. “WW2 Artillery (1939-1945)“. July 27, 2015.

- Kurt Laughlin, Tim Streeter. “105mm Howitzer Ammunition”. Boxes, Bundles, Tubes, and Rounds. 2007

Further Readings

- Joliet Arsenal Development Authority “World War II” Joliet Arsenal History

- Taylor, Stephen Jesse “The Bomb Rooms” WordPress

- Department of the Army “Military Explosives”

- Wikipedia “Joliet Army Ammunition Plant”

- Wikipedia “M101 Howitzer”

- Wikipedia “240mm Howitzer M1”

- Wikipedia “WW2 Artillery”

- Wikipedia “M1 8-Inch Howitzer”